Stamplef

SERVICES

ISO 9001:2015 CERTIFICATION

Quality Management System Certificate

It is hereby declared that the quality management system of the STAMPLEF Ltd. organization complies with the UNI EN ISO 9001:2015 standard for the following products/services:

- Molding

- Blanking

- Welding of metal components

- Assembly of metal components

- Dimensional inspection with 3d measuring machine

DESIGN

Accurate design through CAD and CAM technologies drives the creation of molds, which transform sheet metal into vital components for various industries.

Mold Creation-Maintenance

The creation and maintenance of sheet metal molds are essential to the manufacturing industry. Regular maintenance ensures that the molds maintain their accuracy, optimizing production quality and efficiency. In summary, the synergy between the creation and maintenance of sheet metal molds plays a key role in ensuring high quality results and continuous production.

Cold metal stamping presses

Stamping and Cold Blanking of sheet metal from thickness 0.3mm to 12mm in automatic or manual operation with presses from 30 to 800 tons.

We also provide a mold testing service necessary to verify the efficiency and functionality of the mold, in the presence of the customer, the production manager and the design technician, even on a contract basis, with small batch production.

Dimensional checks with 3d measuring machine

Metrological measuring machine for inspection of manufactured parts.

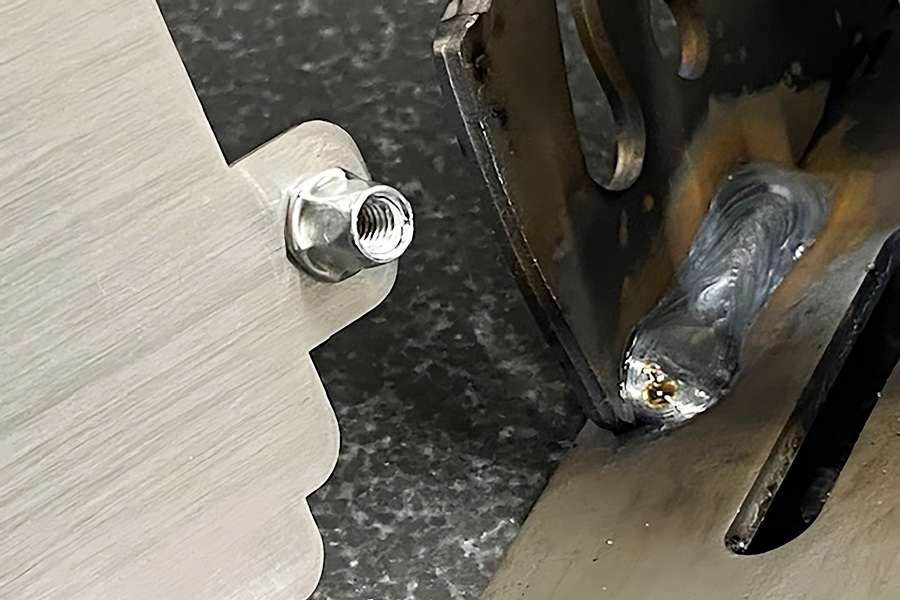

Assembly and Wire Welding

We perform wire welding and assembly by riveting, riveting or insertion of threaded inserts to customer specifications, preventing critical issues that may arise, improving the product itself.

Contact us for your project

We guarantee professionalism and maximum availability and flexibility in all our achievements.